Drawn arc stud welding (ARC)

ARC

Drawn arc (ARC) stud welding with ceramic ferrule or shielding gas

The process drawn arc stud welding is mostly used for stud diameters of 3 to 25 mm and a welding time of 100 to 1 500 ms.

Drawn arc stud welding with ceramic ferrule is recommended for studs with diameter of more than 12 mm. If it is required to protect the weld pool from atmosphere, shielding gas should be used. This process variant is also used with automated applications.

Drawn arc stud welding with ceramic ferrule or shielding gas

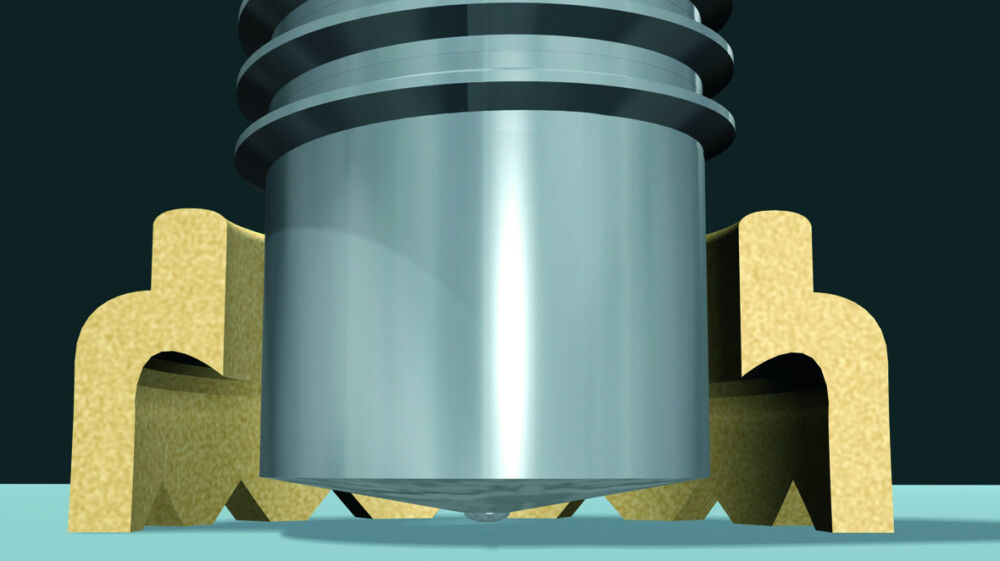

- The stud is inserted into the chuck and - if necessary - equipped with a ceramic ferrule.

- The stud is placed onto the work piece.

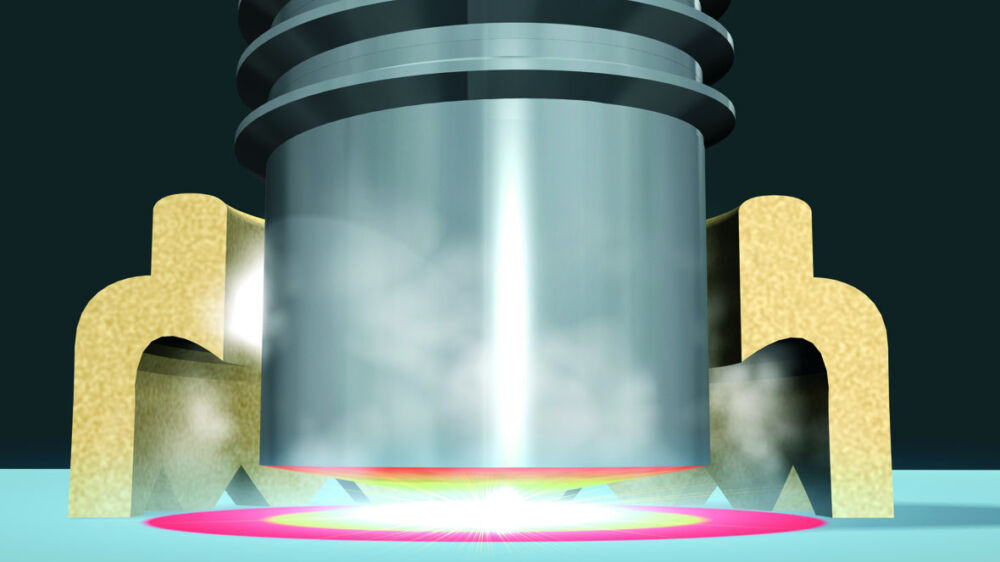

- A lift mechanism in the welding gun or welding head lifts the stud. A secondary arc (pilot arc) of low current is ignited between stud tip and work piece.

- Then the ignition of the main arc is carried out between stud tip and work piece.

- Stud and work piece are melted.

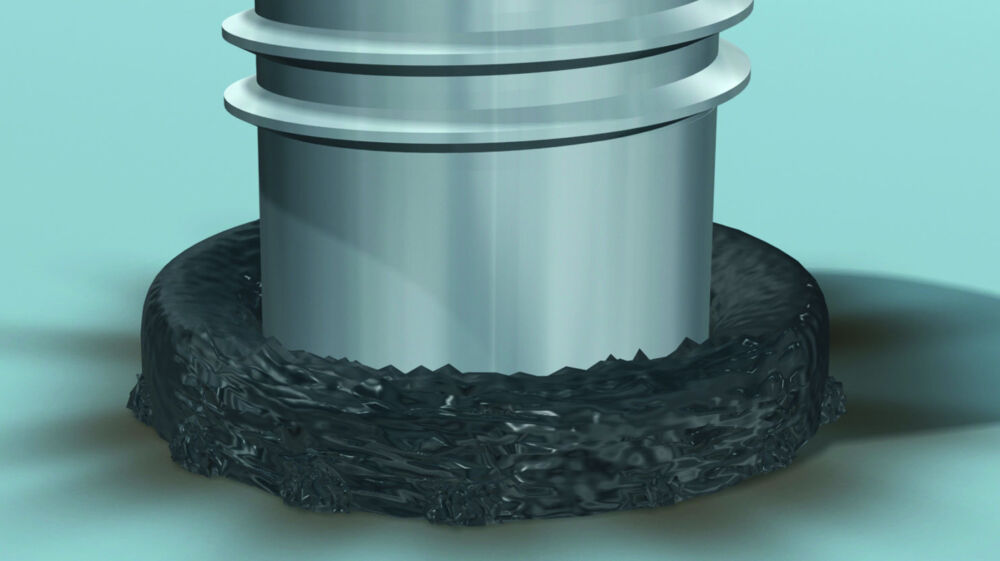

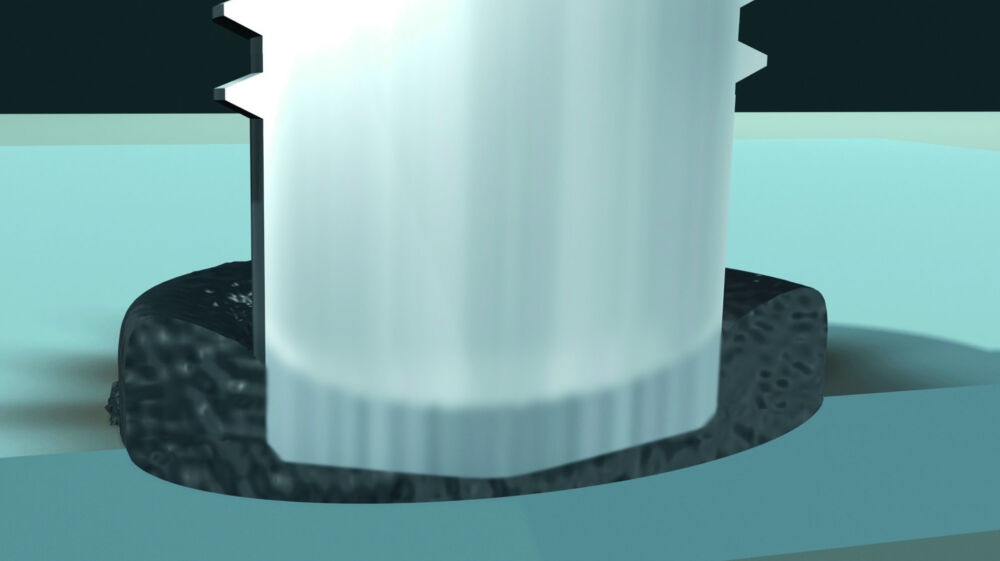

- At the end of the adjusted welding time the stud is moved to the work piece, the two molten zones join. The power source is switched off, the weld pool solidifies and cools down.

Examples of applications drawn arc stud welding (ARC)

ARC Drawn arc stud welding with ceramic ferrule, shielding gas or without.

Specifically designed for thicker sheets of about 2 mm or higher.

Application ranges: steel construction, engineering construction, shipbuilding industry, vehicle construction, structural and civil engineering.