Capacitor discharge stud welding (CD)

CD

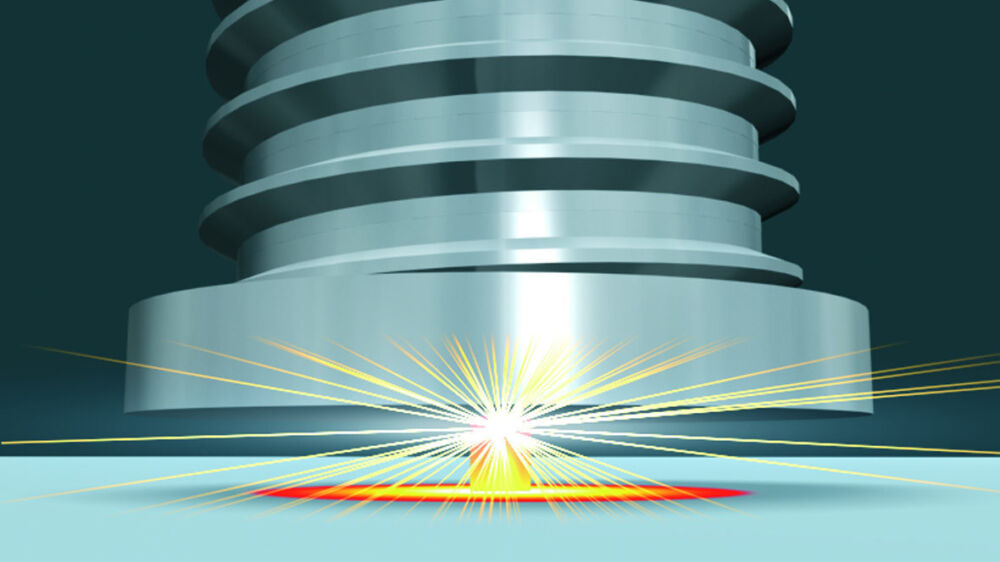

Capacitor Discharge (CD) stud welding with tip ignition

HBS stud welding units provide outstanding reductions in costs and

time. Every weld is precise avoiding any need for post treatment.

Contact or gap

In contrast

to contact welding, with gap welding the stud is positioned at a defined

distance shortly before welding starts. This creates a higher plunging

speed which leads to a shorter welding time (only 1 ms!).

This characteristic also allows welding of touchy materials like e.g. aluminium and brass.

Capacitor discharge stud welding with contact

- The capacitor battery will be charged according to chosen charging voltage.

- The stud (with ignition tip) is placed onto the work piece and pressed by a spring in the welding gun onto the work piece (contact). The current circuit is closed.

- After triggering the welding process, the rapidly increasing current evaporates the ignition tip and ignites the arc.

- Stud and work piece are melted.

- The stud is moved forward to the plate.

- The arc is cut as soon as the stud touches the work piece.

- The molten zones are joining and solidifying.

- Welding time is ≤ 3 msec.

- Recommended plate thickness should be 1/10 d, but not less than 0.5 mm.

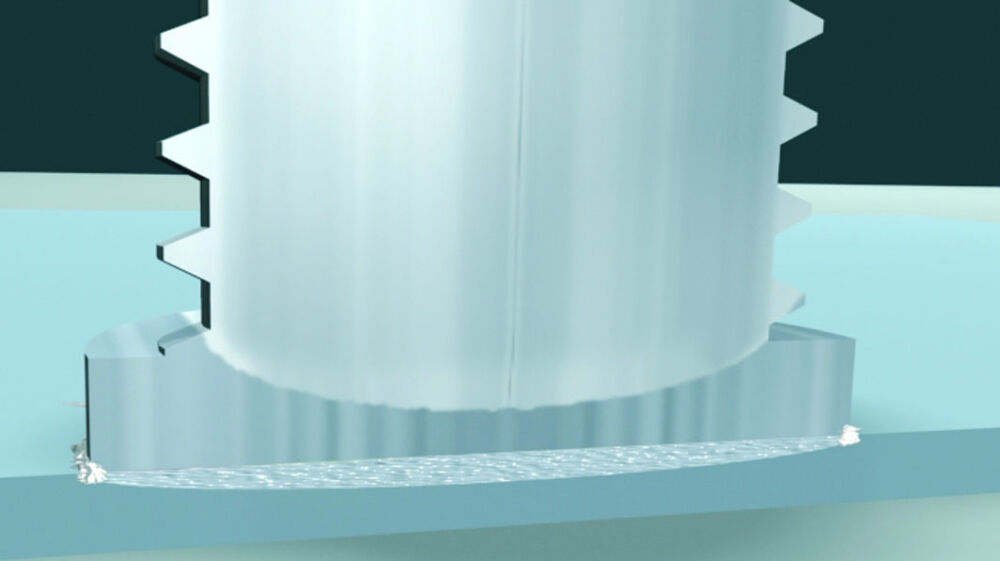

Capacitor discharge stud welding with gap

Gap welding is different from the procedure described above: Before welding starts, the stud is positioned in a defined and adjustable distance above the work piece (gap). After triggering the welding process, the stud is accelerated by a spring to the plate surface. If there is contact between the ignition tip on the work piece, the process continues as described above. Welding time is approx. 1 msec; thus e.g. welding of aluminum becomes feasible without using a shielding gas atmosphere. Recommended plate thickness should be 1/10 d, but not less than 0.5 mm.

Examples of applications capacitor discharge stud welding (CD)

Typical applications include: Sheet metalwork, electronic industries, switchboard cabinets, laboratory and medical equipment, food industry, household appliances, etc. When studs are welded to thin sheets (steel, aluminium and brass), the procedure of tip ignition will always be the most cost effective process and sometimes the only solution.