Short cycle stud welding (SC)

SC

Short Cycle (SC) drawn arc stud welding

High current, shorter duration of welding time

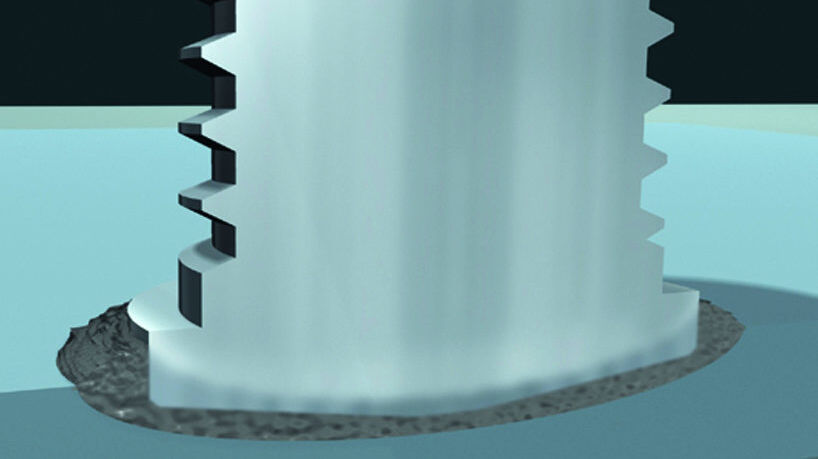

The welding sequence is the same as the sequence of drawn arc welding (ARC), however, with relatively higher currents and shorter welding times (max. 100 ms). The short cycle drawn arc stud welding is suitable for stud diameters up to 16 mm on thin metal sheets.

Without shielding gas

Up to 8 mm stud diameter, the process is often carried out without

weld pool protection. Normally studs with flange are used to achieve

high tensile strengths in spite of pores in the weld zone.

The short cycle process is especially suitable for welding of material combinations like steel (base material), stainless steel (stud) as well as aluminium. To achieve a high welding quality, use of shielding gas is recommended.

Short cycle drawn arc stud welding

- Welding sequence is as with drawn arc stud welding (ARC) with the exception of higher current and shorter welding time (≤ 100 msec).

- This variant is suitable for stud diameters of up to 12 mm to thin plates.

- As the process up to 8 mm is often used without weld pool protection, studs with upset flange are used. In this way, a higher tensile strength of the weld zone is achieved in the welded area than in the stud shaft in spite of the existence of pores.

- From 8 mm stud diameter upwards, a shielding gas should be used to avoid pore formation.

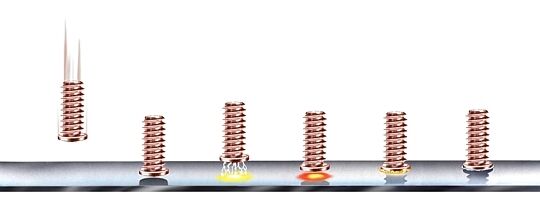

Examples of applications short-cycle stud welding (SC)

With ARC and IT stud welding units for short cycle drawn arc stud welding (with and without shielding gas).

Multiple applications with: studs, tapped pads and pins onto thin metal sheets. A wide field of application is in vehicle construction, in particular using christmas tree studs to fasten conduits and trims